core technology-凯发首页

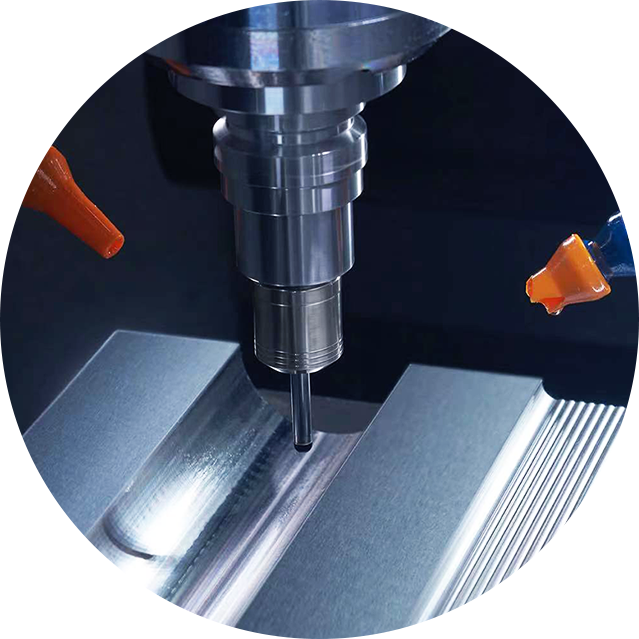

ultrasonic machining technology

processing advantages:

suppress the generation of microcracks

reduce cutting force and improve machining efficiency

extend tool life

reduce workpiece burrs

improving surface quality

supercritical co ₂ low-temperature cooling technology

-78 ° c low-temperature cooling solves the processing difficulties of various difficult to process materials, improving processing efficiency by 50% to 100%

spray medium: low temperature co ₂ (gaseous/dry ice granular)

cooling temperature: minimum can reach -78 ℃

guangdong province famous high tech products

products supported by the national key r&d program manufacturing basic technology and key component key special project "common key technologies for clean cutting"

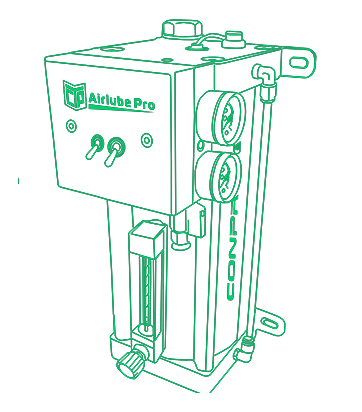

micro lubrication (mql) technology

suitable for cold transfer inside the spindle, the suspended oil particle mist device responds quickly

after switching between different tools, it can automatically adapt to the required amount of lubricating oil

optional gas source boosting system to solve the problem of insufficient pressure and improve the quality of mql oil mist

independently developed patented products

products supported by the national key r&d program manufacturing basic technology and key component key special project "common key technologies for clean cutting"

integrated pcd tool

owning independent intellectual property rights and obtaining 54 domestic and foreign patent certifications

the overall pcd micro blade cutting tool can have more than 300 blades depending on the diameter, resulting in higher efficiency

integrated milling and grinding, with controllable contour accuracy of 3 μ m